Build Better / Condensation Management

Building healthier homes begins with a focus on moisture management

Water is essential for life, because our bodies are 60% water. But it’s different for houses. Chronic condensation inside a house is known as ‘sick home syndrome’ – visible mould and bacterial growth, musty ‘off’ odours, swollen wood and structural damage, damp-feeling surfaces and moist air that’s hard to heat. Sick homes are bad for human health; but they’re also bad for wealth, because they shorten the lifespan of a building.

What causes sick home syndrome?

The sick home problems seen in contemporary homes can commonly be attributed to poor ventilation, weathertightness problems and the wrong sort of building wrap.

Kitchens and bathrooms produce water vapour that saturates the air; building occupants contribute to the moisture load as well, through respiration. A family of four can generate as much as 20 kilograms of water vapour per day.

If the building leaks, external moisture (rain) gets between the exterior cladding of the house and the inside walls. This can cause structural problems for the building and health problems for the occupants.

The principles of moisture management

Everyone working in the construction industry understands the importance of weathertightness, but the principles of moisture management are not so well known. Here’s a quick summary:

- Control liquid water. This means sheltering occupants from rain, as well as melting snow, ice and frost. It also refers to preventing ingress of groundwater and water brought into a building by plumbing.

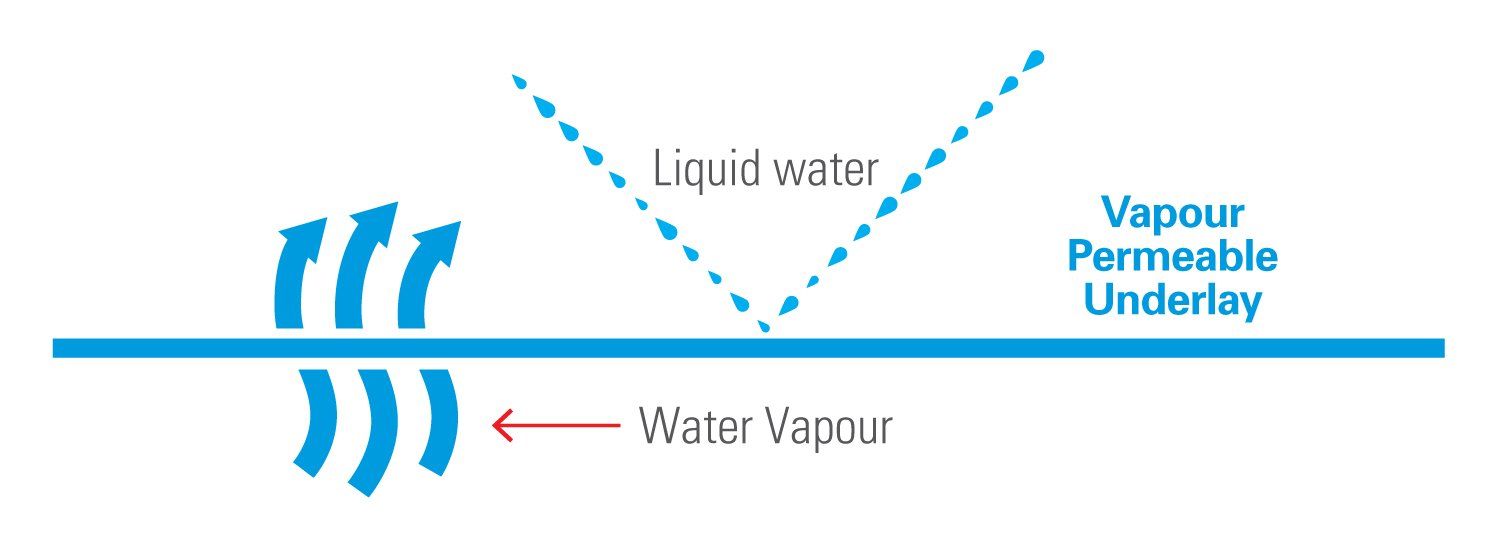

- Manage condensation. Both indoor air and outdoor air holds water vapour. Wherever air goes, water vapour goes. When humid air contacts a cold surface (dew point), the water vapour condenses. Passive management of ventilation requires use of vapour-permeable membranes that allow water vapour to constantly escape.

- Use moisture-tolerant materials. The principle refers to using building materials that can withstand repeated wetting in areas that are expected to get wet.

The NCC has made vapour-permeable membrane wrap mandatory for many major population centres

In 2019, to make Australian homes healthier by improving weathertightness and reducing internal moisture levels, the National Construction Code (NCC) introduced new provisions to improve moisture management.

The new rules make it mandatory to install a vapour-permeable membrane wrap on the outside of insulation in climate zones 6,7 and 8. So from Coff’s Harbour right around to Adelaide, Esperance to Bunbury and all of Tasmania.

Vapour-permeable wraps control moisture from both sides of the problem Roofing underlay, whether it is building paper or a high-tech synthetic underlay, is in close contact with roof cladding. When the temperature drops outside, the cold energy is transferred to the underlay directly beneath the roofing iron or tiles.

Here you can see how vapour-permeable underlays such as Covertek by Thermakraft, provide a barrier to water ingress from the outside while allowing internal vapour to escape.

Why quality should be the first thing you look for in a wrap

Since the introduction of foil-based wraps decades ago, building wraps have evolved significantly. Today’s leading wraps are designed to last for the duration of a building’s life. While they’re more expensive that foil, they bring reliability and long-term durability to your building project. Here’s a checklist of what to look for in a vapour-permeable underlay:

- BRANZ-appraised – wrap properties and durability need to be externally tested and proven

- Permeability – you need to choose a wrap with water-vapour management film technology and performance designed for Australia’s climate conditions Absorbency– to manage surface condensation, look for >100 g/m² for wall underlay and >150 g/m2 for roof underlay

- Fire retardancy – the best wraps contribute to the fire safety of a building

- Quality control – look for in-house batch testing, ISO 9001 accreditation and a 15-year product warranty